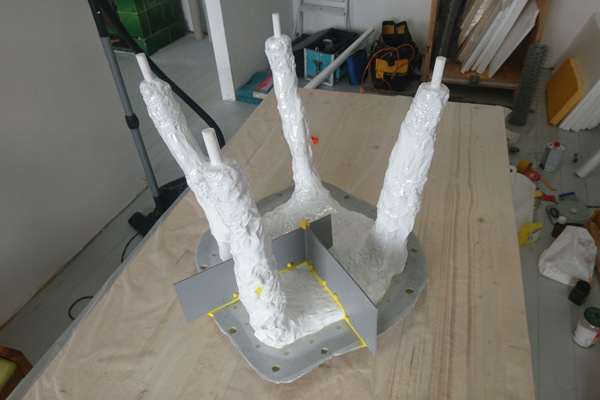

Thanatos Stool Chair Design Process

Design Process

Thanatos Stool Chair Design Process

The Thanatos Stool is inspired by morbid forms and structures at the end of vegetation during autumn.

It represents the result of an intensive one-year research and experimentation in mould making techniques. First, a fragile model from paper was made, after that a master pattern cast in experimental moulds made from silicone rubber and a composite material. Finally, durable silicone block moulds were made to replicate the stool in a larger edition.

For this piece, Philipp Aduatz developed his own material, a resin-marble composite, combining the material advantages of stone and resin polymers. The material is composed from cast resin filled with a marble powder additive, a waste product from marble industry and developed to be ultra-resilient and tough also over a very long time period. Because it is cast in one continuous material, it can easily be refurbished by sanding and polishing as often as necessary. These properties together make it a sustainable and exceptionally long-lasting material.