Digital Chaiselongue Design Process

Design Process

Digital Chaiselongue Design Process

The Digital Chaiselongue emerged from a collaboration of Viennese product designer Philipp Aduatz with Austrian start-up company incremental3d from Innsbruck.

The sculptural design language is realized by the use of an innovative digital fabrication technology that allows to 3D print very detailed concrete geometries in a very fast time. The concept is to use the new technology developed by incremental3d for a complex freeform design by Philipp Aduatz and show the new possibilities of creating complex shapes in an application for furniture design. It is further the aim to show the synergy of the experimental and scientific approach on design by Philipp Aduatz with a company that has developed a new technology and looking for applications.

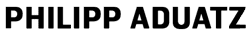

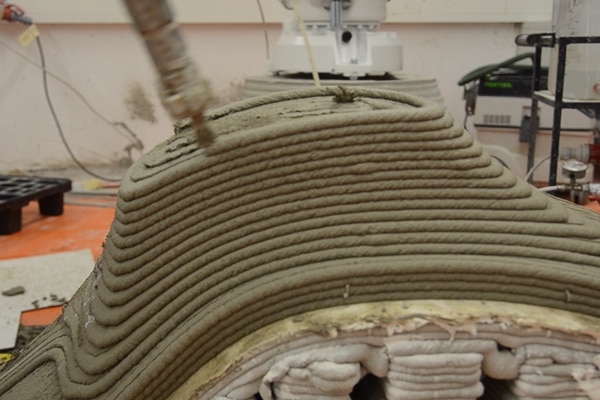

For the Digital Chaiselongue a three-dimensional base plate was first 3D printed from concrete. Afterwards the complete geometry was printed in less than one hour onto the plate. To provide sufficient tensile strength, carbon fibres are inserted in sensitive areas. The seating area was finished by polishing in delicate handcraft, this should demonstrate that craft and digital technologies can coexist for the purpose of innovation in the 21st century in harmony.

Incremental3d is a startup company from Austria founded in September 2017 by Georg Grasser, Johannes Ladinig and Lukas Härtenberger. They have been doing research in the field of concrete printing the last years together at the University of Innsbruck in Austria and have developed a new and innovative technology for concrete 3d printing: unlike other concrete printers, this technology allows to print very fine and detailed freeform geometries very fast with a high resolution closely to the already established Fused Filament Fabrication (FFF) 3D printing technology using polymers. No moulds or support structures are necessary, the freedom of form has a new meaning with this process by using a six-axis robot.

In cooperation with: