APM – Stool Design Process

Design Process

APM – Stool Design Process

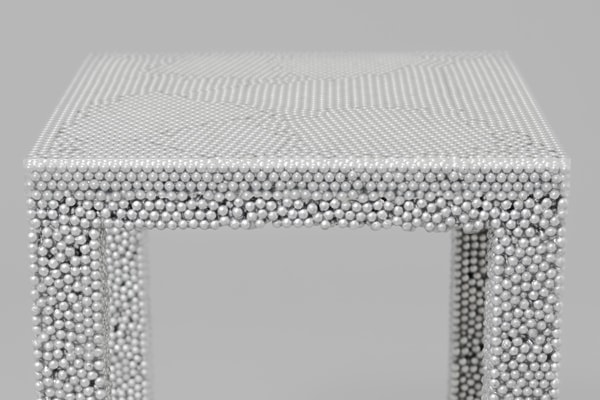

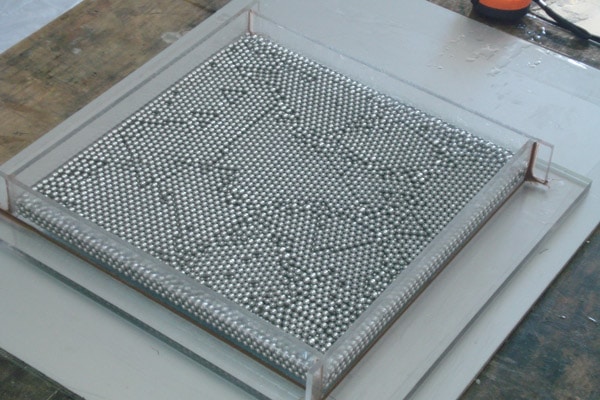

In the APM Stool Philipp Aduatz has created an experimental chair that reflects the aesthetics of modern materials. The APM Stool’s superior design is based on the contrast between simplicity and solidity of form and the seemingly instable structure of the plastic bullets. As during the production process by which the bullets are consolidated the amassment follows the law of chance each piece is unique.

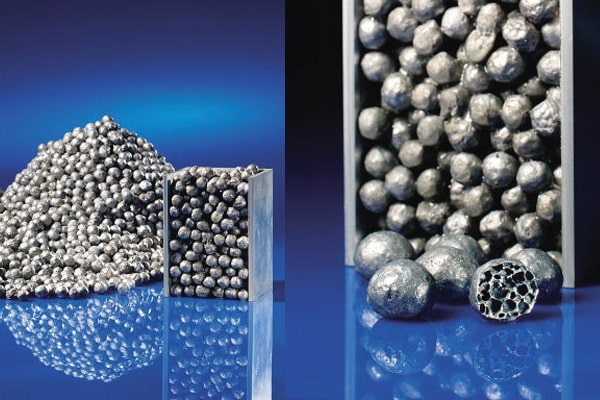

The reason for the APM Stool’s design can be derived from Aduatz´ fascination of the complexity and elegance of cellular solids, which are also the topic of his Ph. D thesis at the University of Applied Arts Vienna. APM stands for advanced pore metallurgy and the APM foams are developed at the Fraunhofer Institute in Germany. Large objects are constructed from metallic foam, by the adhesive bonding of tiny foam spheres to a certain shape. The thirty thousand plastic bullets of Philipp Aduatz´ APM Stool were arranged with moulds and then glued together with epoxy resin.